BLUF (Bottom Line Up Front)

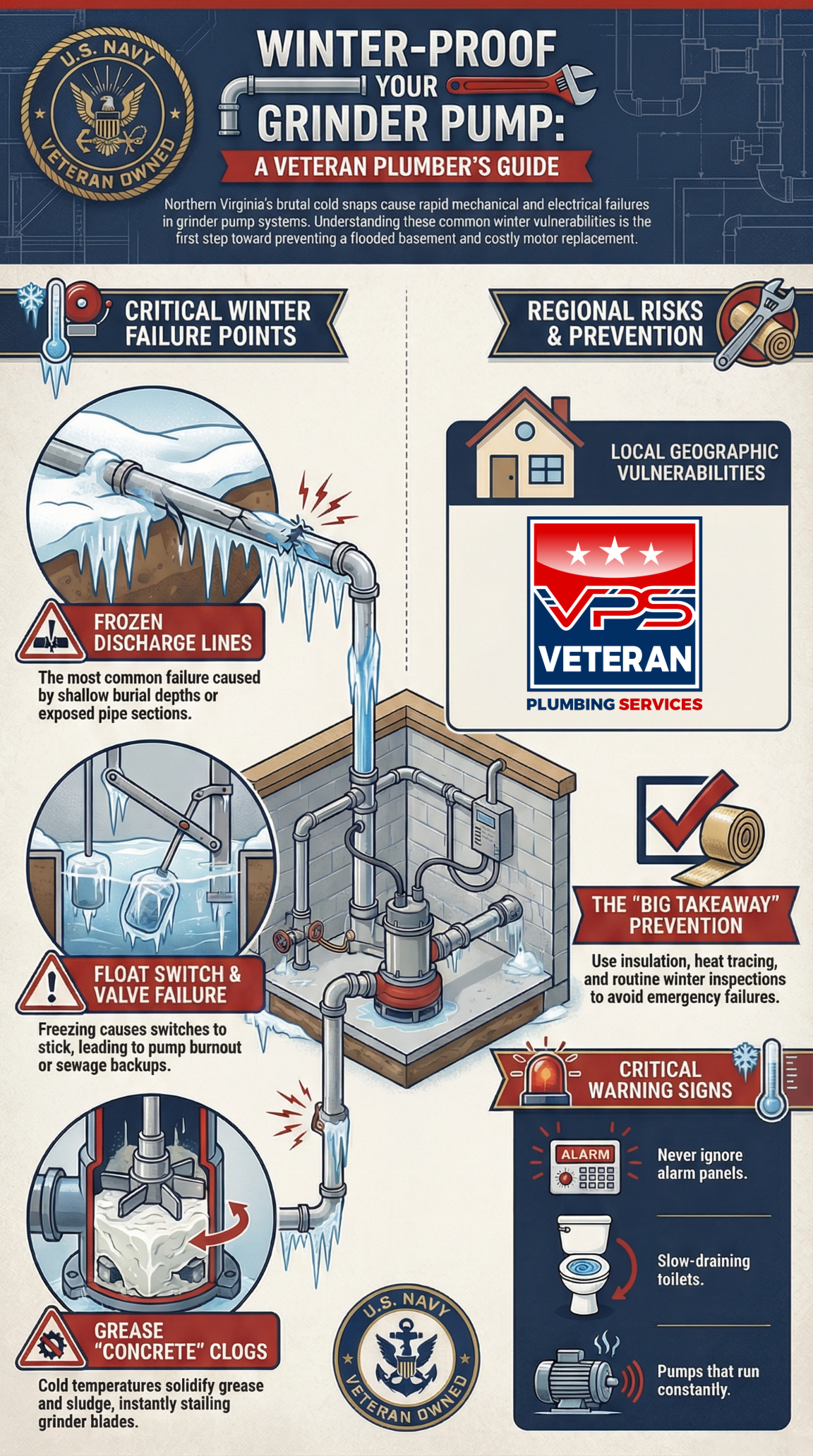

Cold-weather grinder pump failures in Culpeper, Fauquier, Stafford, Loudoun, Prince William, and Fairfax Counties are not random events. They are the direct result of freezing discharge lines, poorly sealed or insulated basins, stuck float switches, thickened grease and sludge, frozen check valves, and electrical issues caused by rapid freeze-thaw cycles. When temperatures drop quickly, grinder pumps are forced to operate against ice, heavier waste, and restricted flow, resulting in alarms, backups, motor overload, and, in many cases, total pump failure. In my experience as a retired U.S. Navy Chief and owner of Veteran Plumbing Services, most winter grinder pump emergencies are preventable through proper burial depth, insulation, sealed lids, routine inspections, and fast response when alarms activate. Ignoring cold-weather warning signs almost always turns a manageable winter repair into an expensive system replacement.

Introduction

I am Dennis Rollins, a retired U.S. Navy Chief and the owner of Veteran Plumbing Services. Every winter, I see the same phone calls come in from homeowners across Culpeper County, Fauquier County, Stafford County, Loudoun County, Prince William County, and Fairfax County. Temperatures drop rapidly, alarms sound, toilets stop flushing properly, and basements begin to smell like sewage.

Grinder pumps do not fail randomly in cold weather. They fail for specific reasons tied to temperature, soil depth, wastewater behavior, and installation choices made years or even decades ago. In this article, I am going to walk through every major grinder pump issue caused by freezing temperatures in Northern Virginia and explain what is actually happening underground when the mercury drops.

Why Cold Weather Is So Hard on Grinder Pump Systems

Grinder pumps rely on three things working together. Moving water, mechanical components, and electrical controls. Freezing weather attacks all three at the same time.

Northern Virginia winters are not consistently cold. We get rapid temperature swings. One week it is fifty degrees, the next week it drops into the teens overnight. That rapid freeze-thaw cycle is what causes most grinder pump failures in this region.

In counties like Culpeper and Fauquier, long rural pipe runs are common. In Loudoun, Prince William, and Fairfax, shallow utility corridors and dense housing developments create different but equally dangerous risks. Stafford sits right in the middle with a mix of older installations and newer construction.

Frozen Discharge Lines Are the Number One Failure

What the Discharge Line Does

The discharge line carries ground wastewater from the grinder pump basin to the sewer main or septic system. When this line freezes, the pump has nowhere to send waste.

Why Discharge Lines Freeze in These Counties

In my experience, discharge lines freeze for several reasons.

The pipe was buried too shallow

The line runs long distances across open ground

Insulation was never installed or has deteriorated

The pipe exits the foundation above the frost line

This is extremely common on larger properties in Culpeper and Fauquier, where homes sit far from the sewer connection or septic tie in.

What Homeowners Notice First

The pump alarm goes off

Toilets drain slowly or back up

The pump runs continuously without clearing the basin

When a pump tries to push wastewater against a frozen pipe, it strains the motor. That strain is what turns a minor freeze into a full pump replacement.

Grinder Pump Basin Freezing

How the Basin Freezes

The grinder pump basin is supposed to stay warm enough underground to prevent freezing. When the lid is not sealed properly or insulation is missing, cold air drops straight into the basin.

Standing wastewater freezes from the top down. Once ice forms, internal components stop moving freely.

Where I See This Most Often

Rural homes with above grade basins

Older installations retrofitted into existing homes

Second homes that sit unused during cold snaps

When a basin freezes, the damage can include cracked basin walls, seized impellers, and broken internal fittings.

Float Switch Failures in Freezing Temperatures

Why Float Switches Matter

Float switches tell the grinder pump when to turn on and off. They move up and down with wastewater levels.

What Cold Weather Does to Floats

Ice locks floats in place

Condensation freezes around pivot points

Debris frozen in place traps the float

When floats fail, one of two things happens. The pump never turns on and wastewater backs up, or the pump never shuts off and overheats.

This is very common in Loudoun and Fairfax where grinder systems are often installed near exterior walls and garages.

Pump Motor Overload and Burnout

Cold Thickens Wastewater

Cold weather changes how wastewater behaves. Grease hardens. Sludge thickens. Flow slows down.

The grinder pump motor has to work harder to move thicker material through partially frozen pipes.

How Motors Fail

Thermal overload trips repeatedly

The motor overheats internally

Windings burn out

Once a grinder pump motor burns out, repair is rarely possible. Replacement is usually the only option.

Check Valve Freezing and Backflow Problems

What the Check Valve Does

The check valve prevents wastewater from flowing back into the basin after pumping.

What Happens in Freezing Weather

Moisture inside the valve freezes

The valve locks shut or partially closed

Pressure builds in the discharge line

A frozen check valve causes alarms, short cycling, and repeated pump starts, which shorten the system’s life.

Electrical and Control Panel Issues During Cold Snaps

Cold Does Not Just Affect Pipes

Grinder pumps rely on electrical control panels, alarms, and power supplies. Cold weather creates condensation, which can lead to electrical issues.

Common Winter Electrical Failures

Moisture freezing inside control panels

Corroded terminals from freeze thaw cycles

GFCI outlets tripping repeatedly

This is especially common after snow followed by sunny days when melting water refreezes overnight.

Grease and Sludge Solidification

Winter Turns Grease Into Concrete

In cold weather, grease behaves like glue. In grinder systems, grease sticks to basin walls, impellers, and floats.

Holiday cooking makes this worse. I see a spike in grinder pump failures after Thanksgiving, Christmas, and New Year gatherings.

What This Causes

Impellers jam

Floats stick

Pumps stall under load

This kind of failure is often misdiagnosed as an electrical issue when it is actually a buildup problem made worse by cold temperatures.

Power Outages and Winter Storm Damage

Power Loss Is a Hidden Risk

Winter storms cause outages across all six counties. When the power goes out, grinder pumps stop working immediately.

Wastewater continues to enter the basin, but nothing moves it out.

What Happens When Power Returns

Frozen components try to start at once

Overloaded motors fail instantly

Frozen discharge lines block flow

This is why so many grinder pump failures happen right after storms, not during them.

Why Northern Virginia Counties Are Especially Vulnerable

Culpeper and Fauquier have long rural runs and septic integrations

Stafford and Prince William have mixed era installations

Loudoun and Fairfax have shallow utilities and dense development

These systems were often installed to meet minimum code at the time, not to withstand modern freeze patterns.

The Bottom Line on Cold Weather Grinder Pump Failures

Grinder pump failures in winter are not bad luck. They are predictable, repeatable, and preventable.

Insulation matters

Burial depth matters

Proper venting and sealing matters

Routine winter inspections matter

When alarms go off during freezing weather, ignoring them almost always turns a manageable repair into a full replacement.

I have spent years responding to winter grinder pump emergencies across Northern Virginia. The homes that avoid disaster are the ones that prepare before temperatures drop.

If your grinder pump system has never been evaluated for cold-weather performance, winter is not the time to guess. The cost of prevention is always less than the cost of cleanup.

📞 Call Veteran Plumbing Services today at 703-791-1339

I’m Dennis Rollins. I served my country, and now I’m here to help you protect your home.

📞 Schedule online Veteran Plumbing Services Anytime, 24 hours a day.