From the Desk of Dennis Rollins, U.S. Navy Veteran & Owner, Veteran Plumbing Services

Here is the simple truth about tankless water heaters in Fairfax, Loudoun, and the surrounding counties:

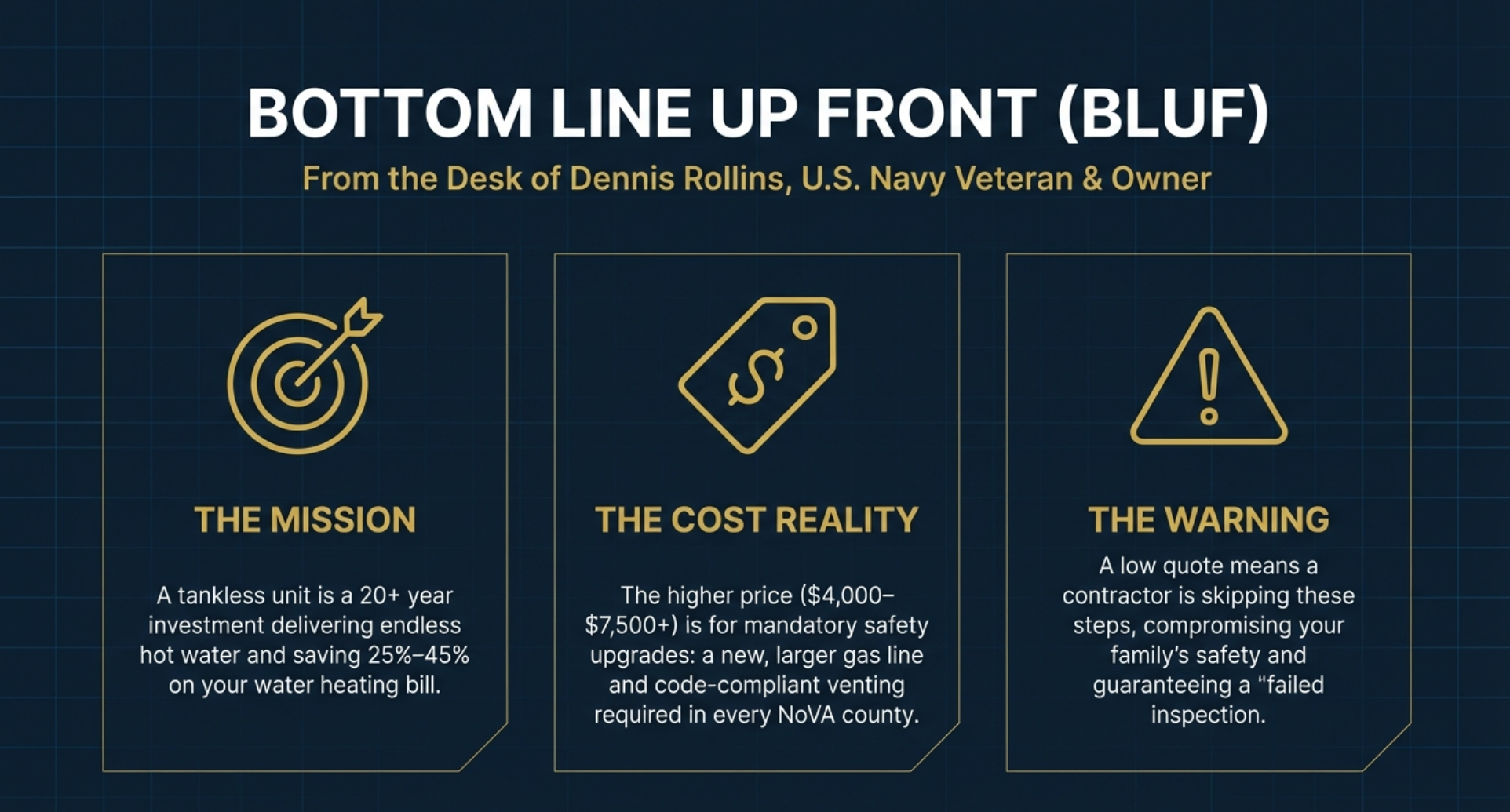

The Mission: A tankless unit is one of the best investments you can make, delivering endless hot water and saving you 25%–45% on your water heating bill for 20+ years.

The Cost Reality: The higher initial installation price (often $4,000–$7,500+) is not for the unit itself. It is for the mandatory safety and infrastructure upgrades—specifically, running a new, larger gas line and installing specialized, code-compliant venting—required by every county in Northern Virginia. You cannot skip the county permit.

The Warning: If a contractor quotes you a low price and skips these gas line and venting upgrades, they are compromising your family’s safety and guaranteeing a failed final inspection.

The Solution: Hire a Master Gasfitter who guarantees a code-compliant installation, secures your permit, and sizes the unit correctly (for cold NoVA winters). We turn a complex, high-risk upgrade into a seamless, high-efficiency operation that is built to last. Invest once, correctly, and enjoy guaranteed savings and performance for decades.

Table of Contents

The Homeowner’s 6-Chapter Guide to Tankless Water Heaters in Northern Virginia

- BOTTOM LINE UP FRONT (BLUF): The Mission, Cost Reality, and Warning for NoVA Homeowners

- Chapter 1: The Financial Reality (Cost, Savings, & Rebates)

- Chapter 2: Sizing, Selection, and Performance

- Chapter 3: Navigating Local Permits and Codes

- Chapter 4: Installation Requirements, Location, and Hard Water

- Chapter 5: The Installation Day: A Step-by-Step Mission Briefing

- Chapter 6: Vetting Contractors and Final Inspection

Chapter 1: The Financial Reality (Cost, Savings, & Rebates)

The Financial Reality of Tankless Water Heaters in Northern VirginiaThe first time a homeowner calls me to ask about a tankless water heater, the conversation always turns to one mission-critical topic: money.

In the Navy, we planned every mission with meticulous attention to resources and long-term costs. When you’re considering an upgrade as significant as a tankless water heater in your Fairfax, Loudoun, or Prince William home, your approach should be no different. You see the benefits—endless hot water, reclaiming storage space—but you’re naturally looking at the bottom line, asking: “Is the steep upfront cost truly worth the investment?”

My job is to cut through the noise and give you a disciplined, honest assessment of the financial reality. I’m not here to sell you on a gadget; I’m here to show you the math that proves why a properly installed tankless unit is one of the best investments you can make in your Northern Virginia home’s efficiency and value.

In this chapter, we will tackle the financial questions that matter most:

- Why is the installation so much more expensive? (Hint: It’s safety and code compliance.)

- How quickly will the unit pay for itself in energy savings?

- How can we use local utility rebates and federal tax credits to bring the cost down immediately?

Let’s deploy.

1.1 Understanding Upfront Costs vs. Total Lifetime Cost: The Upgrade Factor

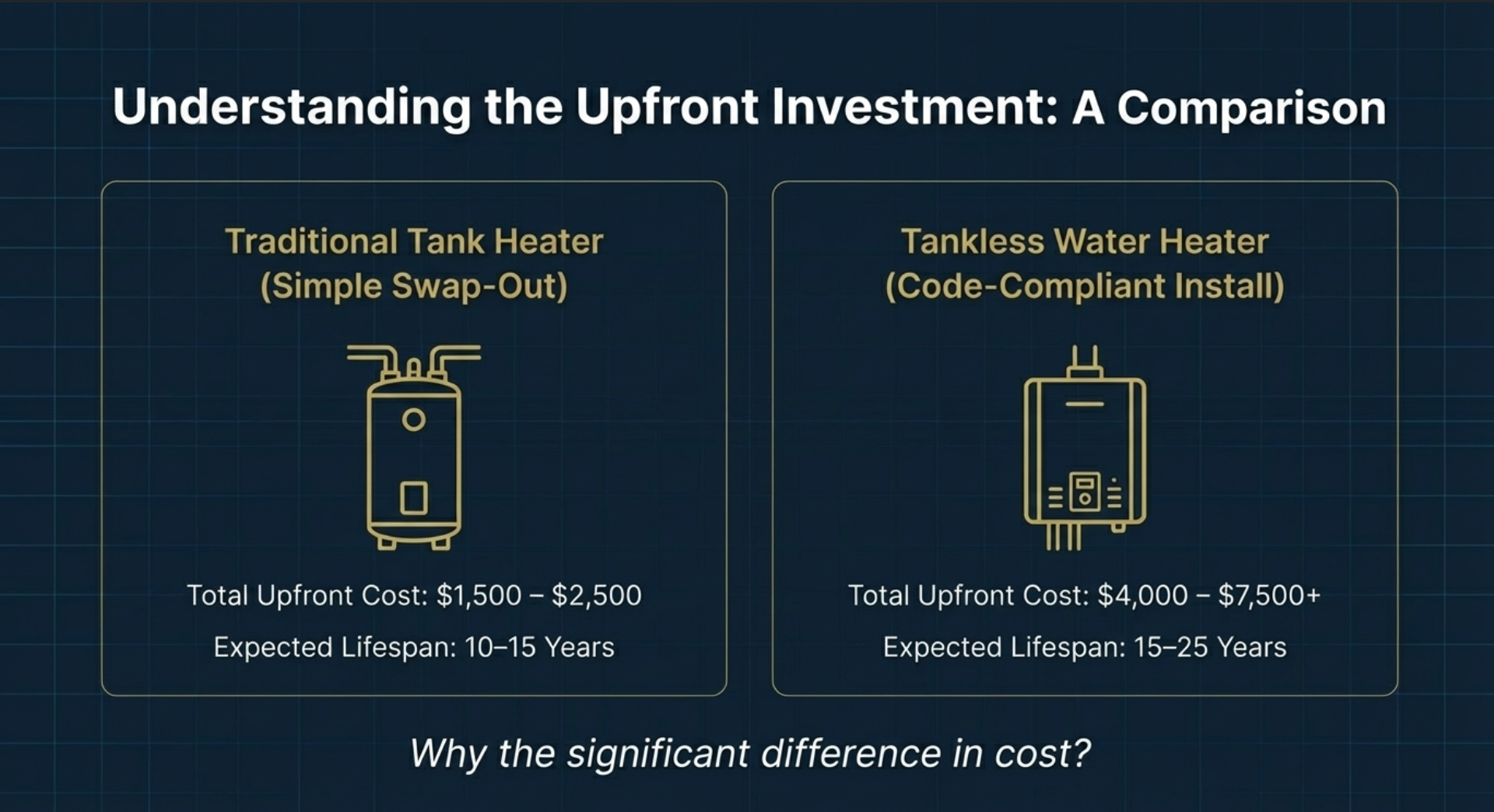

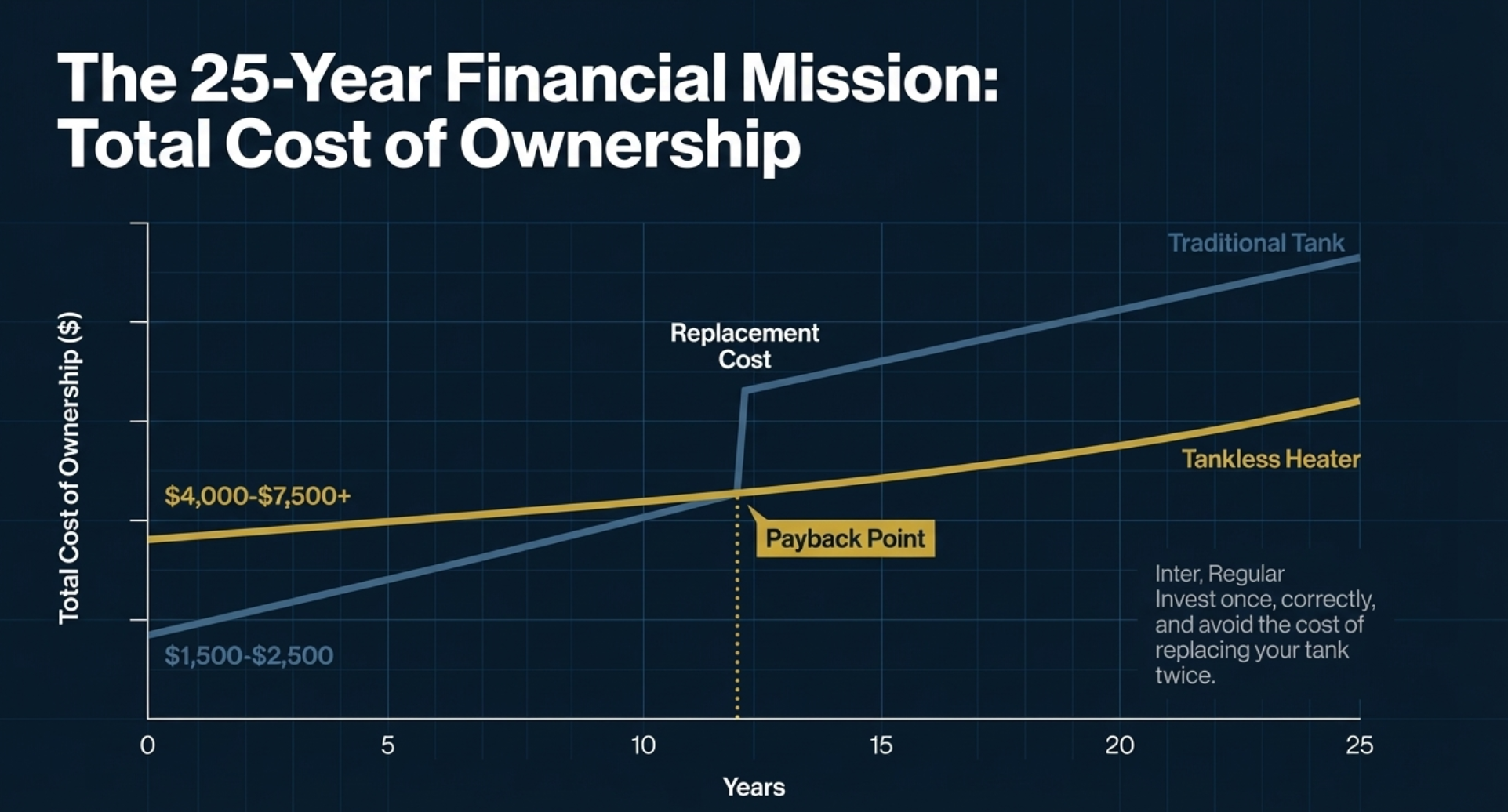

The most common point of sticker shock for homeowners is the initial installation price tag. Let’s be honest: a standard replacement for your traditional 50-gallon tank might run you $1,500 to $2,500 total. A high-efficiency gas tankless installation, however, can efficiently run $4,000 to $7,500 or more, depending on your home’s existing infrastructure.

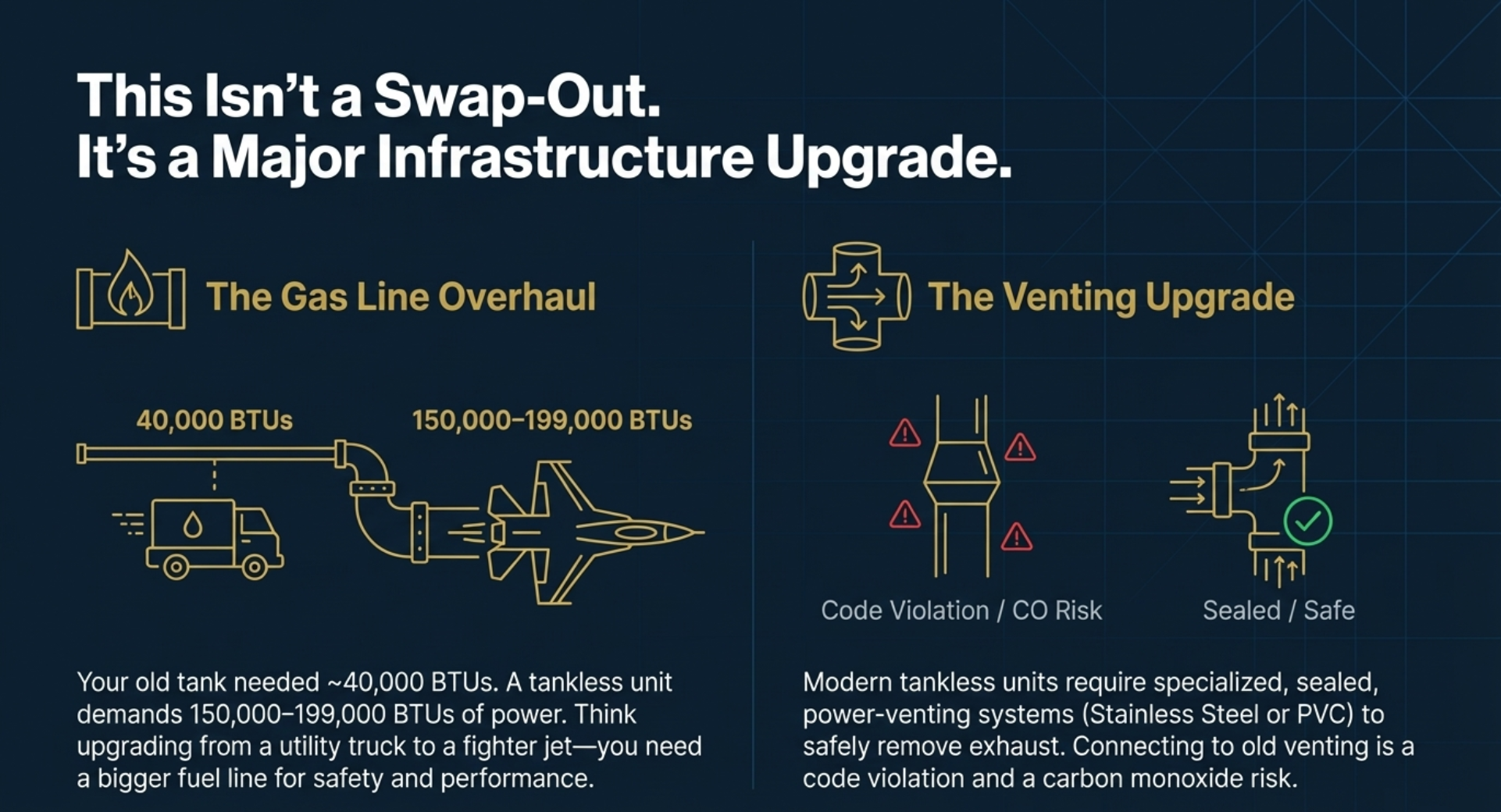

I want you to understand precisely why that cost is higher. It is not because the tankless unit itself is inherently a miracle device. It is because we are not doing a simple “swap-out.” We are performing a major infrastructure upgrade on two mission-critical systems: your gas supply and your ventilation.

The Gas Line Overhaul (The BTU Requirement)

Your old storage tank was probably rated at around 40,000 BTUs (British Thermal Units). It took its time to heat a reservoir of water and then just kept it warm, humming along at a low draw. Your new high-performance gas tankless heater, which can heat water instantly and continuously for two showers and a dishwasher at once, needs explosive power. These units are typically rated at 150,000 to 199,000 BTUs.

Think of it like upgrading from a small utility truck to a high-speed fighter jet—you need a much bigger fuel line.

In the vast majority of our installations across Stafford, Culpeper, and Prince William counties, the existing gas line serving the old tank is not large enough to deliver that massive new gas load safely and efficiently. If we were to connect the new tankless unit to an undersized line, you would experience “cold water sandwiches”—a burst of hot water, then cold, then hot again—because the unit is starving for fuel. More dangerously, undersizing a gas line is a code violation that can lead to gas pressure issues and safety hazards.

So, part of the installation cost is running a brand-new, dedicated, properly sized gas line from the meter or the main manifold to the new tankless unit. This involves more labor, materials, and specialized gasfitting expertise, all of which are factored into the higher initial price.

The Venting Upgrade (Safety & Code Compliance)

Your old tank likely vented its exhaust gases (including carbon monoxide) up a B-vent or into a masonry chimney through natural drafting. This will not work for a new tankless unit.

Modern, high-efficiency tankless units use sealed, power-venting systems (either Category III Stainless Steel or specific PVC materials). They use a fan to force the exhaust outside. The installation of this new, high-efficiency, code-compliant vent—which requires us to drill a precise hole through your foundation or wall and ensure strict clearances from windows and doors—is a complex process that demands a certified mechanical gas fitter.

Any plumber who tries to tell you they can connect the new tankless unit to the old venting system is putting your family at risk and guaranteeing a failed county inspection in Fairfax, Loudoun, or anywhere else. We refuse to compromise on safety.

| Cost Factor | Traditional Tank Heater (Simple Swap) | Tankless Water Heater (Code-Compliant Install) |

| Unit Cost | $500 – $1,500 | $1,500 – $4,500 |

| Installation Labor | Low (3-5 hours) | High (6-10 hours, often two technicians) |

| Infrastructure Upgrades | Minimal | New Gas Line and New, Sealed Venting |

| Total Upfront Cost | $1,500 – $2,500 | $4,000 – $7,500+ |

| Expected Lifespan | 10–15 Years | 15–25 Years |

The Longevity Argument

Here is the financial pivot point: A tankless water heater, with its robust components and lack of a rusting steel reservoir, lasts up to twice as long as a traditional tank. When you factor in the cost of replacing a traditional tank twice over 25 years, the financial scales tip heavily in favor of the tankless unit. You are buying quality and peace of mind for the long haul.

1.2 Operating Costs and Energy Savings: The ROI Engine

The higher initial cost is the necessary sacrifice to unlock your true Return on Investment (ROI), which comes through energy savings.

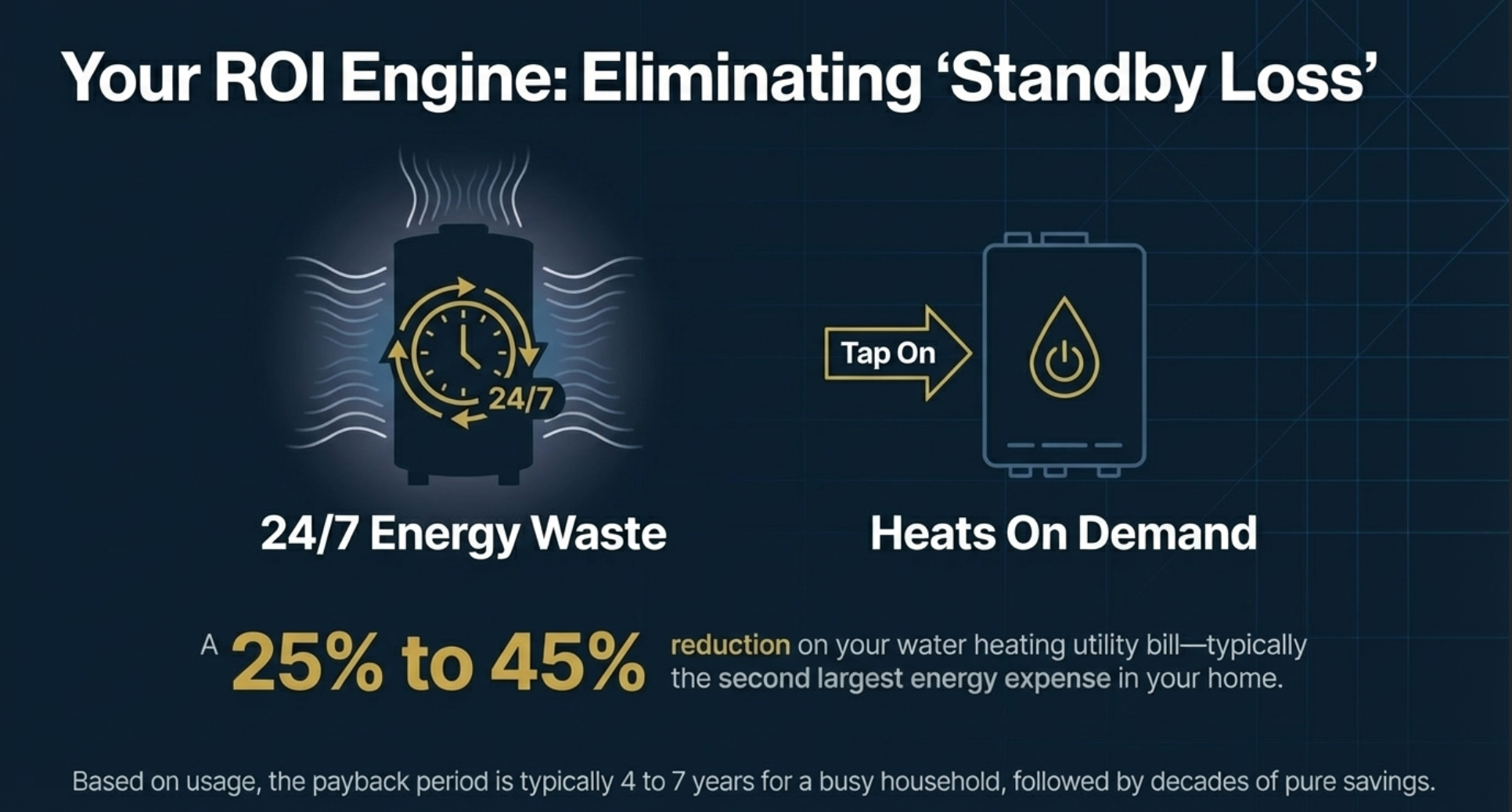

Eliminating Standby Loss

The fundamental flaw of the conventional water tank is the concept of standby loss. Your tank is constantly using energy to keep 50 or 60 gallons of water hot, 24 hours a day, even when you’re asleep, at work, or on vacation. That’s pure waste. You are paying to heat water you are not using.

A tankless water heater operates like a well-trained soldier: it only activates when called upon. When you turn on a hot water tap, the unit senses the flow, ignites its powerful burner, and heats the water instantly. When you turn the tap off, the unit shuts down completely.

This simple operational difference translates to significant savings. According to ENERGY STAR, for homes that use 41 gallons or less of hot water daily, tankless water heaters can be 24%–34% more energy efficient than conventional storage tank water heaters. For homes that use a lot of hot water—like most of the larger, multi-bath homes we service in Loudoun and Fauquier counties—the savings can be as high as 50%.

My Estimate: For a typical Northern Virginia household with above-average water usage, we generally see a 25% to 45% reduction in your water heating utility bill. Since water heating is often the second largest energy expense in your home (after your HVAC system), that adds up fast.

Calculating Your Payback Period (The ROI)

The payback period—the time it takes for your monthly savings to cover the installation premium—varies based on your unit choice, installation cost, and, most critically, your home’s hot water usage.

- Low Usage: If your household uses hot water sparingly, your payback period will be more extended, perhaps 8 to 10 years.

- High Usage: If you have teenagers, multiple bathrooms, or a busy household, your savings are much higher, potentially leading to a payback period of 4 to 7 years.

Given that the unit is expected to last 15 to 25 years, you can expect many years of pure realized savings once it has paid for itself. This is a disciplined, long-term financial victory.

1.3 Maximizing Savings with Local & Federal Incentives: The Smart Money

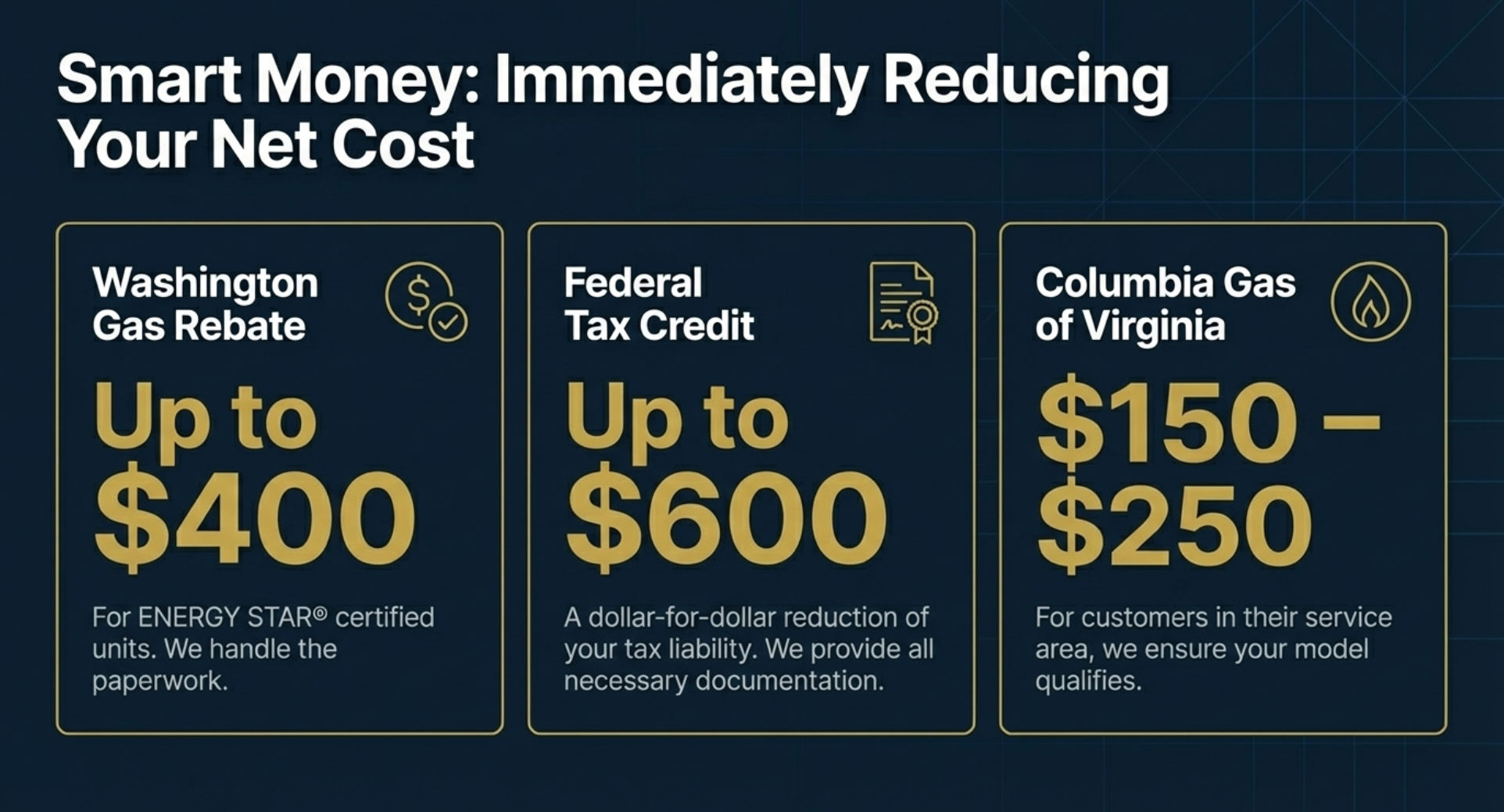

You can immediately offset a substantial portion of the high installation cost by leveraging local utility rebates and federal tax credits. My team at Veteran Plumbing Services makes sure we spec out a unit that qualifies for every available program.

Washington Gas Rebates (For Customers in Fairfax, Loudoun, etc.)

Washington Gas is one of the best programs in our service area. If Washington Gas services your home, you may be eligible for a rebate of up to $400 on a high-efficiency, ENERGY STAR® certified natural gas tankless water heater.

Key Requirement: We must ensure the specific model we install is on their approved list and has the required Uniform Energy Factor (UEF). We handle the paperwork, making it a seamless process for you. This $400 is money back in your pocket right off the bat.

Columbia Gas of Virginia (WarmWise Program)

If you are a Columbia Gas customer (typical in parts of Prince William and Stafford), their WarmWise program offers rebates for high-efficiency natural gas models, often ranging from $150 to $250. Again, we select a model that meets their UEF requirements to ensure you get the maximum rebate.

Federal Tax Credit (The Energy Efficient Home Improvement Credit)

Due to recent legislation (the Inflation Reduction Act), homeowners who install highly efficient equipment may qualify for the Energy Efficient Home Improvement Credit. For a qualifying ENERGY STAR certified unit, you can claim a tax credit of up to $600.

It’s critical to understand the distinction: this is a credit, not just a deduction. It is a dollar-for-dollar reduction of your tax liability. We provide all the necessary paperwork and model numbers so your tax professional can easily claim this credit, further reducing your net cost.

The Financial Summary: A Discipline of Savings

When we combine the savings:

- $400 (Washington Gas Rebate)

- $600 (Federal Tax Credit)

- Decades of 25%-45% utility bill reduction.

The financial decision becomes clear. The upfront investment, once mitigated by incentives and framed against decades of low operating costs and no-replacement expense, is the fiscally disciplined choice for a responsible homeowner.

Now that we’ve established the financial case, let’s move on to the performance questions. You need to know that the unit we install can handle the peak demand of your busy Northern Virginia household. In Chapter 2, we will break down the crucial concept of Gallons Per Minute (GPM) and how we properly size a unit to ensure you truly have endless hot water.

Chapter 2: Sizing, Selection, and Performance

In the previous chapter, we established that the tankless water heater is a sound financial investment over the long term. But money only matters if the unit actually performs its duty.

The most frequent question I face from homeowners, especially those in the larger custom homes of Loudoun, Fauquier, and western Prince William County, is this: “Will this small box truly keep up with my family? Will I run out of hot water?”

My answer is direct: You will never run out of hot water if we size it correctly. If we size it wrong, the unit will struggle, and you will have a poor experience, regardless of how much money you save on your gas bill.

This chapter is dedicated to the technical precision required for selecting the right model. We will discuss the two critical factors that determine performance: Gallons Per Minute (GPM) and the unique challenge of Temperature Rise in the Northern Virginia climate. Finally, we will settle the debate over Gas vs. Electric for whole-home applications.

2.1 The Critical Factor: Gallons Per Minute (GPM)

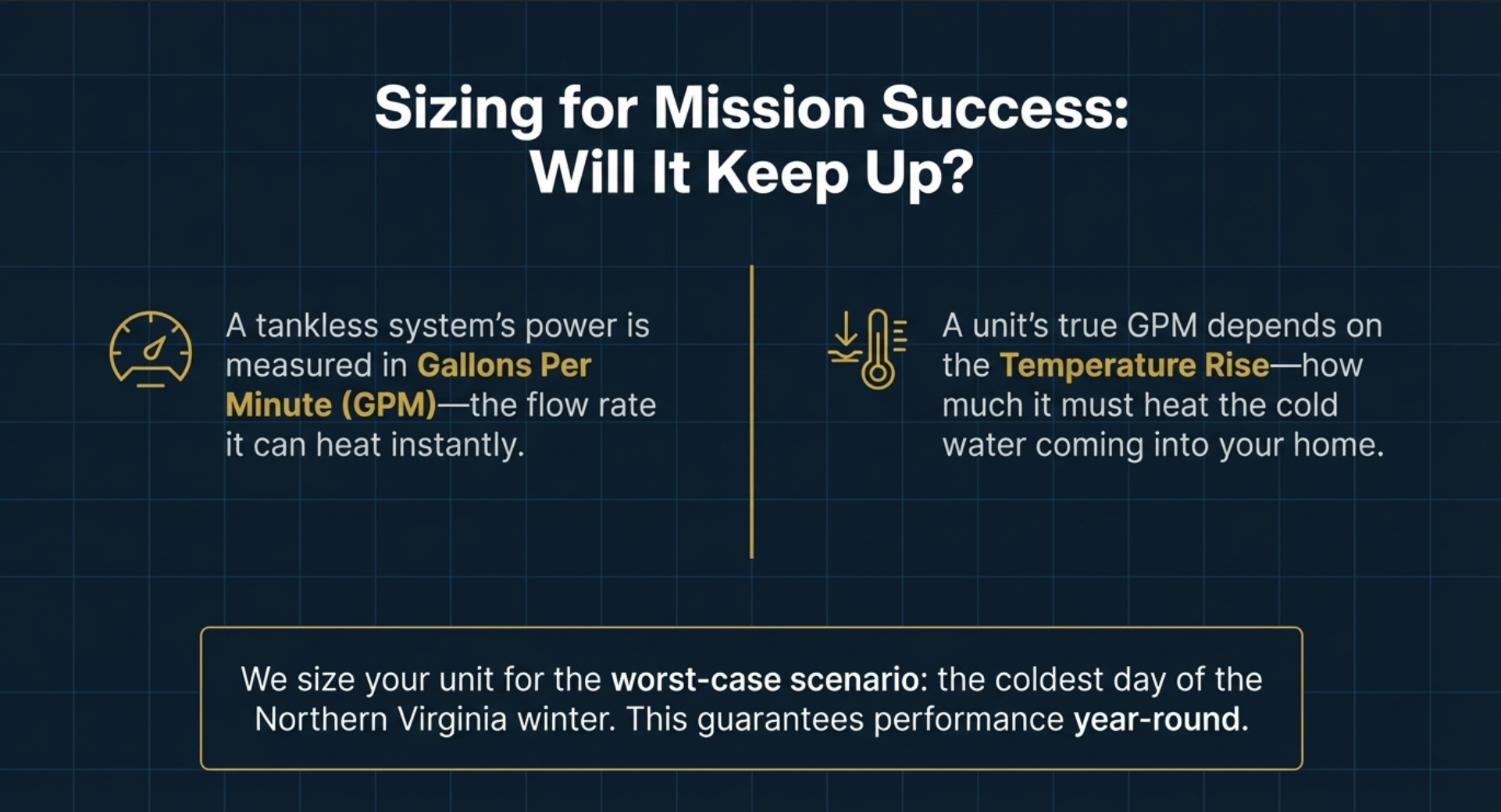

To properly size a tankless unit, we must understand how it delivers hot water. A tank system works on volume (gallons stored). A tankless system works on flow rate, measured in Gallons Per Minute (GPM).

The GPM rating tells you the maximum flow the unit can heat to your desired temperature at a given moment. However, the manufacturer’s GPM rating on the box is often highly misleading, and here is why: It does not account for the Temperature Rise required in your specific location.

The Mission Variable: Temperature Rise

When planning a mission, you must account for all variables. In water heating, the most significant variable is the groundwater temperature—the temperature of the water entering your home from the utility line. The unit must raise that incoming water temperature to your desired outgoing temperature (typically 120°F). The difference between the two is the Temperature Rise.

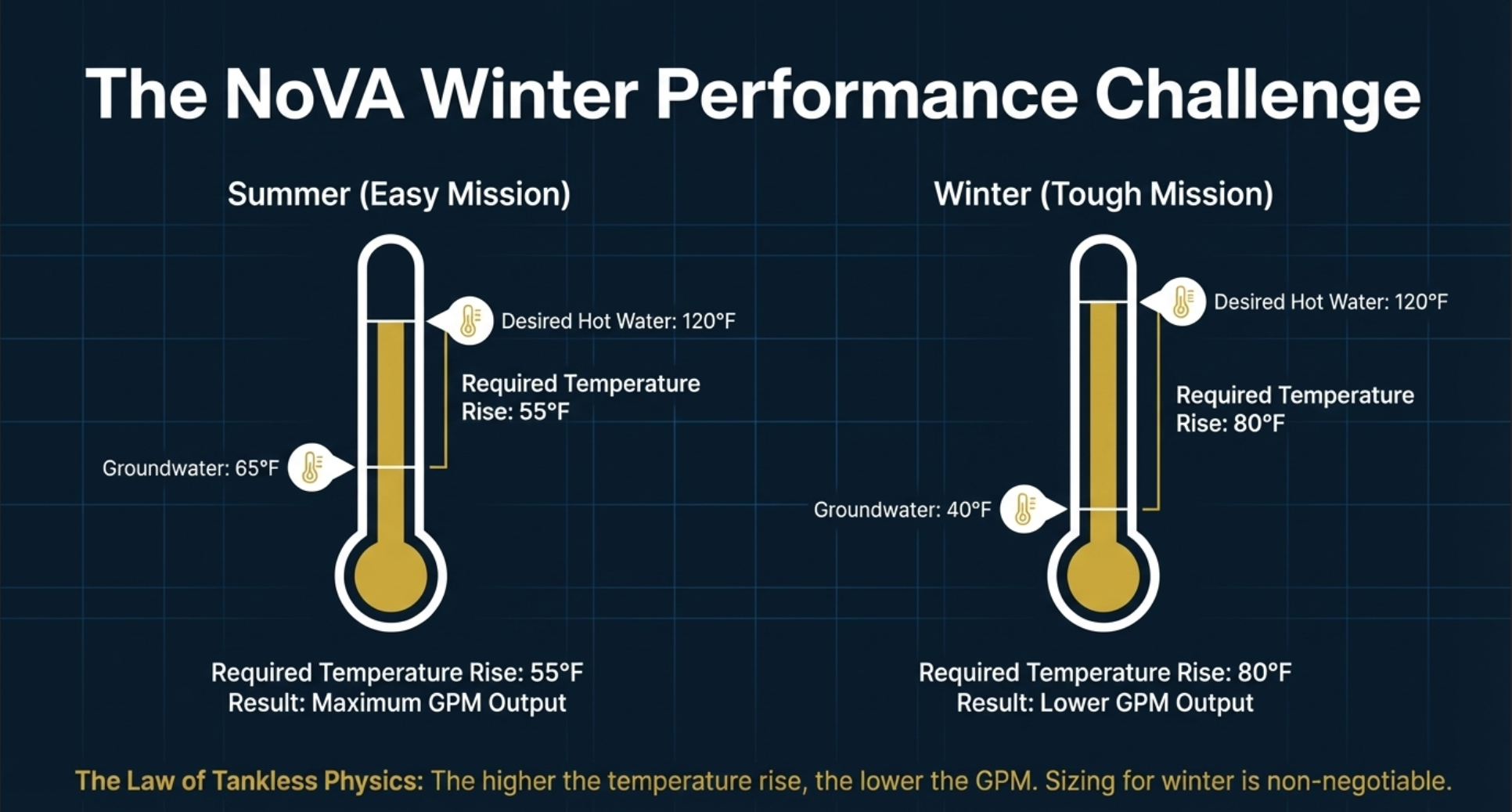

- Summer Performance (Easy Mission): In the summer, the incoming groundwater temperature in the NoVA area might be a comfortable 65°F. To reach 120°F, the unit only needs a 55°F Temperature Rise. At this lower demand, a standard unit can achieve its maximum GPM.

- Winter Performance (Tough Mission): In the dead of winter in Culpeper, Stafford, or western Loudoun, the incoming groundwater temperature can plummet to as low as 40°F. To achieve the same 120°F water, the unit now requires a staggering 80°F Temperature Rise.

The Law of Tankless Physics: The higher the temperature rise demanded, the lower the unit’s GPM output.

Therefore, when my team and I size a unit for your home, we only look at the worst-case scenario: the winter performance. If the unit can keep up with your family’s peak demand on the coldest day of the year, it will excel the rest of the time. This disciplined, worst-case planning is essential to prevent performance failure.

2.2 Peak Demand: Calculating Your Household’s Mission Profile

Now that we know we have to size for winter, we need to calculate your household’s Mission Profile, or its peak simultaneous demand. This is the maximum amount of hot water that will be drawn at the same instant.

We don’t care about the total number of fixtures—we care about how many high-demand fixtures are likely to be running at the same time during the busiest hour of the day (usually mornings or evenings).

Here is a typical GPM demand breakdown we use for our calculations:

| Hot Water Fixture | Typical GPM Demand |

| High-Efficiency Shower | 2.0 – 2.5 GPM |

| Standard Shower | 2.5 – 3.0 GPM |

| Dishwasher | 1.0 – 2.0 GPM |

| Clothes Washer | 1.5 – 3.0 GPM (during the hot cycle fill) |

| Bathroom Sink | 0.5 GPM |

Example Sizing Scenarios for NoVA Homes:

-

Scenario 1: The Standard Suburban Home (Fairfax or Prince William)

- The Mission: A teenager is showering (3.0 GPM), a parent is running the kitchen sink/dishwasher (1.5 GPM), and a laundry machine is filling (2.5 GPM).

- Peak Demand: 7.0 GPM.

- The Result: We must select a unit rated to deliver at least 7.0 GPM at an 80°F Temperature Rise. A unit undersized for the kitchen sink alone would result in lukewarm water in the shower.

-

Scenario 2: The Large, Custom Home (Loudoun or Fauquier)

- The Mission: Two showers are running simultaneously (6.0 GPM total), a soaking tub is filling (4.0 GPM), and the dishwasher is on (1.5 GPM).

- Peak Demand: 11.5 GPM.

- The Solution: No single, practical tankless unit can meet this demand. The correct, code-compliant solution is installing two high-efficiency units in a manifold (or cascading) system. This allows them to work together, guaranteeing the flow rate and temperature stability you need.

My team performs this detailed, conservative sizing audit for every quote. We select the unit’s BTU power to meet your winter GPM requirement. This disciplined approach ensures that your system is always competent and ready for action.

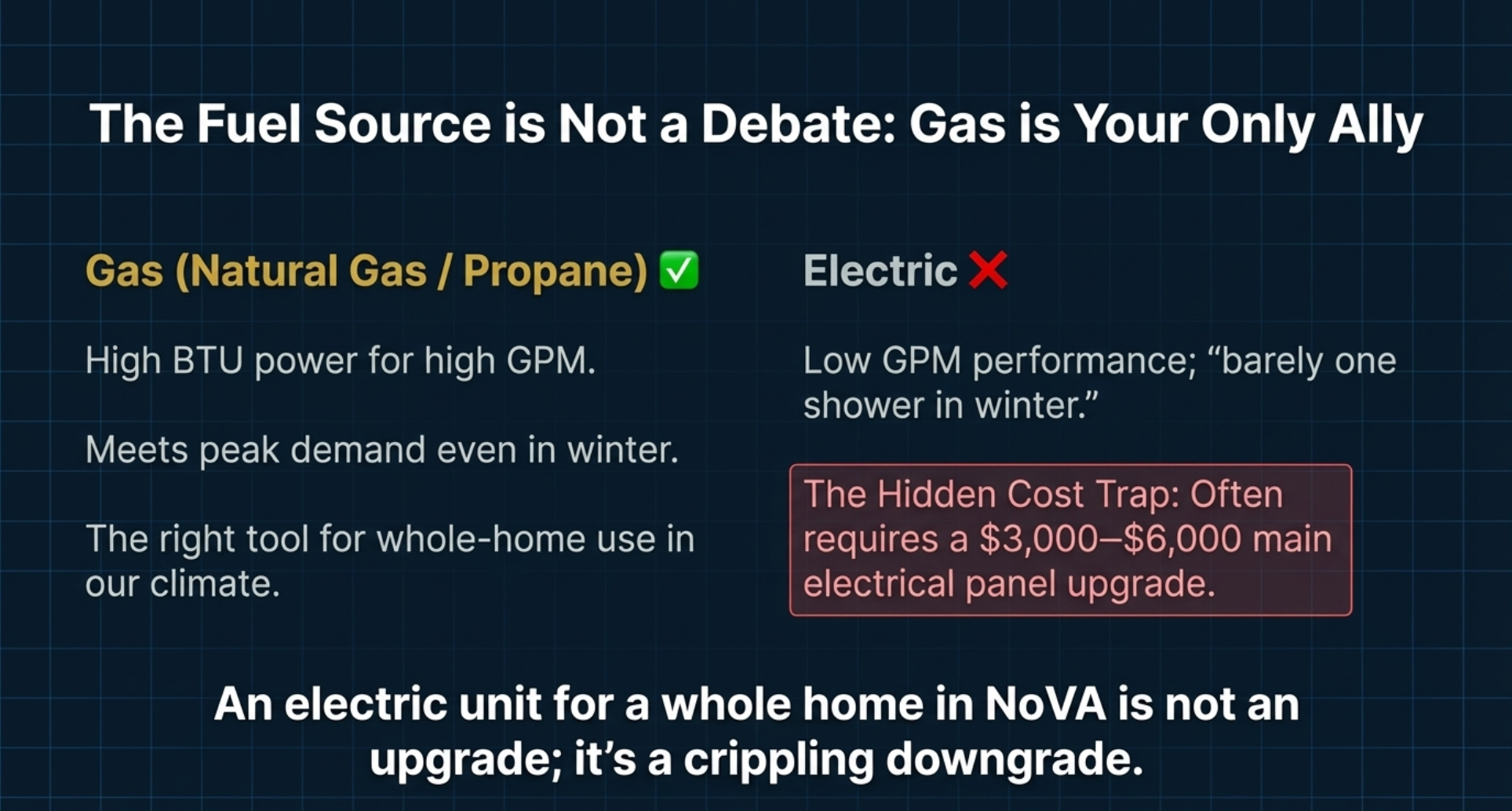

2.3 Gas vs. Electric: Choosing Your Fuel for the NoVA Climate

I tell every homeowner in our service area the same thing: For whole-home hot water, especially in the Northern Virginia climate, you want a Gas (Natural Gas or Propane) Tankless Unit.

The math is simple: Gas units have the power (the high BTU) needed to deliver the high GPM you need to meet the peak simultaneous demand of a modern home, particularly during the high-temperature-rise requirements of winter.

The Reality of Electric Tankless

Many manufacturers advertise their electric tankless units as cheap, easy to install, and perfect for saving space. This is a partial truth that often leads to disappointment and massive costs for the homeowner.

-

Low Performance Barrier: Electric tankless heaters cannot deliver the GPM needed for a multi-fixture home. A typical whole-home electric unit may only deliver 2.0 GPM at an 80°F Temperature Rise (winter). That is barely enough for one modest shower, let alone two, plus laundry. If you buy an electric unit for your family’s house in Stafford, you are effectively trading your old tank’s limit of 50 gallons for a new, permanent limit of one fixture at a time. This is not an upgrade; it’s a crippling downgrade.

-

The Electrical Upgrade Trap (The Hidden Cost): To achieve even modest flow rates, electric tankless units draw an enormous amount of power, typically requiring 150 to 200 AMPS of dedicated service. The majority of older homes in the NoVA suburbs (built in the 70s, 80s, and 90s) simply do not have the electrical capacity. If you try to install one, you will likely need to:

- Upgrade your main electrical panel from 100 or 150 AMPS to a 200+ AMP service by PRO Electric plus HVAC.

- Run massive, dedicated wiring from the panel to the unit.

- This electrical work alone can cost $3,000 to $6,000 and will undoubtedly require a separate electrical permit and inspection.

In my experience, the money saved on the unit itself is quickly negated—and often exceeded—by the required, non-negotiable electrical infrastructure upgrade.

My Recommendation: Save the electric tankless unit for Point-of-Use applications—for example, a small unit installed under a sink in a far-away garage apartment or a renovated basement bathroom that is too distant from the main unit. For whole-home use, Gas is the only dependable, performance-driven choice.

With the unit sized for your family’s mission profile and the correct fuel source determined, we are ready to move on to the most complex and critical part of this process: installation and county compliance. In Chapter 3, we will dive into the permit requirements across Fairfax, Loudoun, Prince William, and the surrounding counties, and detail the necessary gas line and venting upgrades that ensure the safety and legality of your new high-efficiency system.

Chapter 3: Navigating Local Permits and Codes

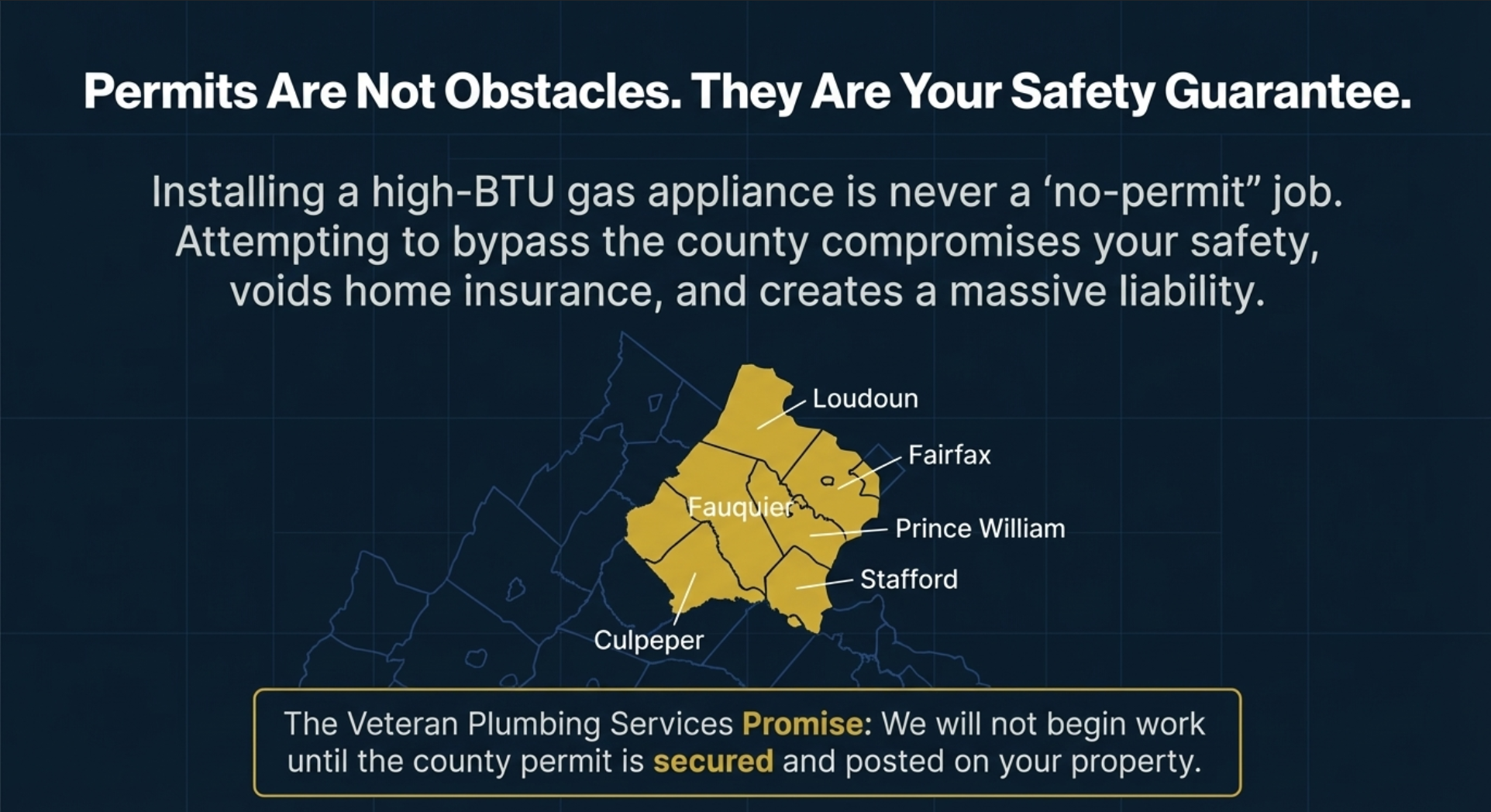

In the military, we understood that rules and regulations are not obstacles; they are the framework for a successful, safe operation. In the civilian world of plumbing and gasfitting, the rules are defined by the Virginia Uniform Statewide Building Code (USBC), enforced by your local county.

This chapter is the most critical for homeowners in Fairfax County, Loudoun County, Prince William County, Culpeper County, Fauquier County, and Stafford County, because it directly addresses the number one area where untrained plumbers fail: Code Compliance.

I hear the same question constantly: “Can’t we just skip the permit? It’s just a water heater replacement.”

My immediate, non-negotiable answer is: Absolutely not. Installing a gas tankless water heater is a complex change to your home’s gas and mechanical systems. It is never a “no-permit” job. Attempting to bypass the county permit process is a dangerous gamble that compromises your safety, voids your home insurance, and creates a massive liability when you eventually sell your home.

3.1 The Permit Requirement: A Universal Mandate

Whether we’re working on a new subdivision home in Loudoun or an established house in Fairfax, the rule is the same: A permit is required for any alteration to a fuel-fired appliance, gas piping, or venting system.

The reason is simple and tied directly to the high BTU demands we discussed in Chapter 1: We are replacing a low-BTU natural-draft appliance with a high-BTU power-vented appliance. This requires a safety review by the county to ensure:

- Carbon Monoxide Safety: The new venting system is properly sealed and terminates safely away from windows, doors, and air intakes.

- Gas Delivery Safety: The upgraded gas line can handle the massive BTU load without causing pressure drops or, worse, dangerous leaks.

- Fire Safety: The appliance is installed with the required clearances from combustible materials.

County-Specific Permit Types

While the State Code is uniform, the specific permit titles differ slightly. When you hire Veteran Plumbing Services, we manage this entire process for you, from application to final inspection.

| County | Required Permit(s) | Key Inspection Focus |

| Fairfax County | Household Appliance Permit (or Residential Plumbing Permit for piping) | Gas line sizing, Venting clearances, Elevation (if in garage). |

| Loudoun County | Plumbing and Mechanical Permit | Proper installation of isolation valves, Combustion air access, TPR valve discharge. |

| Prince William County | Gas Permit (often tied to a Mechanical Permit) | New gas line pressure test, Connection to common venting systems (strictly regulated). |

| Culpeper County | Plumbing and Mechanical/Gas Permit | Location relative to living spaces, Proper installation of the condensation drain (if required). |

| Fauquier County | Residential Building Trade Permit (Plumbing/Mechanical/Gas) | Gas line sizing calculation submission, Venting materials (must be approved type). |

| Stafford County | Appliance Permit (or Residential Change Building Permit) | Protection from mechanical damage (if installed in an attic or exposed area), Accessibility for service. |

The Veteran Plumbing Services Promise:

We will not begin the installation until the county permit is secured and posted on your property. This is a non-negotiable safety and legal commitment.

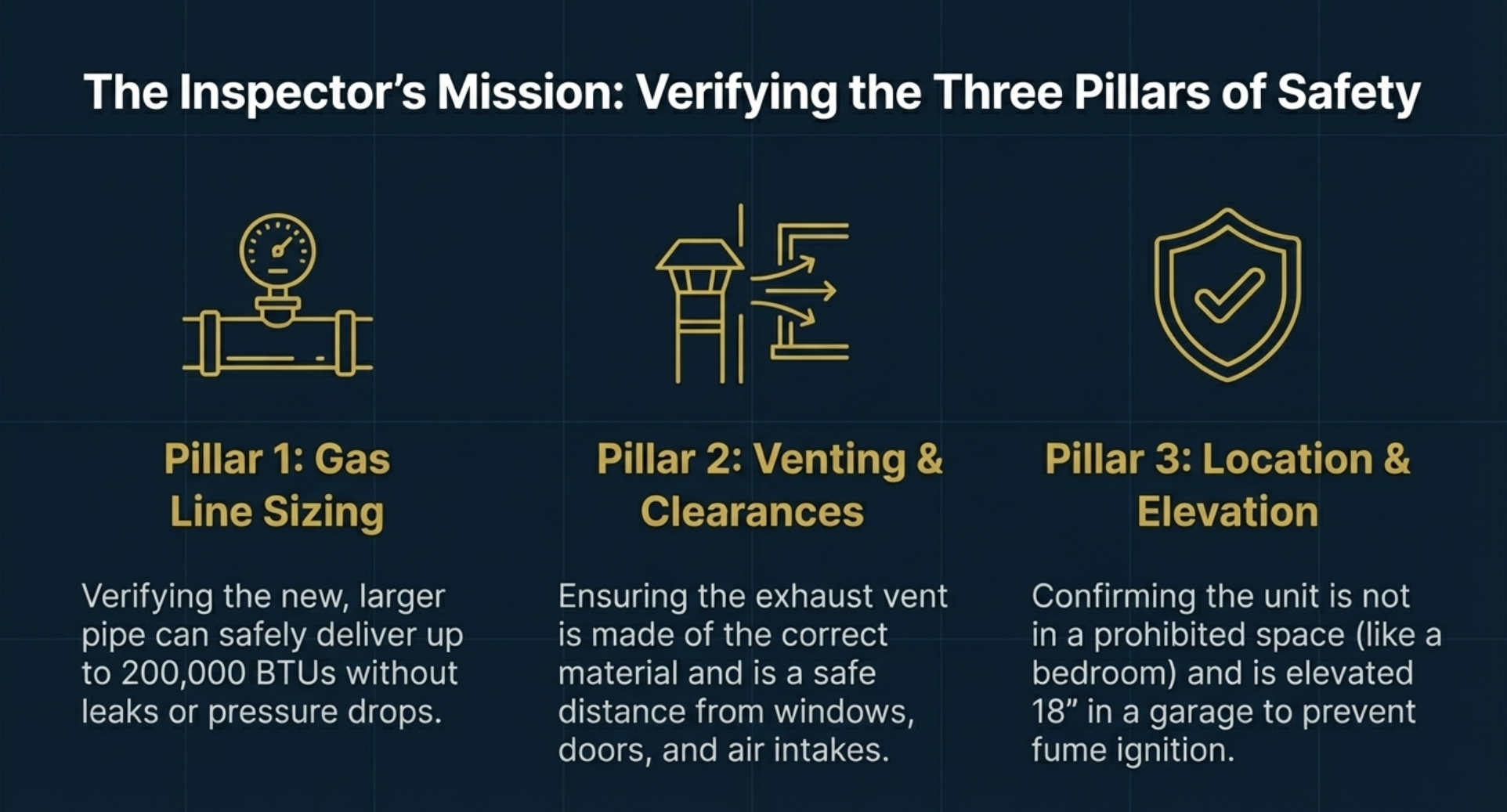

3.2 Code Compliance Focus: The Three Safety Pillars

When the county inspector arrives at your home, be it in Stafford or Loudoun, they will be looking for three specific safety elements that most often lead to a failed inspection for inexperienced contractors. We treat these three points as our mandatory check-off list.

Pillar 1: Gas Line Sizing (The BTU Audit)

As detailed in Chapter 1, this is the most common reason for failure. The inspector’s job is to verify that the newly installed gas piping can safely and correctly deliver up to 200,000 BTUs to the new appliance.

- The Contractor’s Duty: We must perform and submit a Gas Piping Sizing Calculation (usually based on a code-compliant method, such as the NFPA 54 Tables). This calculation proves that the gas pipe’s diameter and length are sufficient for your tankless unit and all other gas appliances in your home (furnace, stove, dryer, etc.).

- The Inspector’s Check: The inspector will visually check the new pipe’s diameter and location and may request to see the pressure test results to ensure the integrity of the new line.

If the gas line is undersized, the system will not pass inspection, and the plumber will be forced to return, tear out, and replace the line—a massive, expensive headache for all involved. We build it to code from the start.

Pillar 2: Venting Requirements and Clearances

Since we are installing a high-powered, power-vented system, the exhaust gases must be dealt with precisely. The vent’s termination point is critical.

- Proximity to Openings: The vent exhaust cannot be located within specific horizontal and vertical distances from windows, doors, property lines, and, most importantly, air intake vents (like your HVAC intake or dryer vent). The code has strict, non-negotiable measurements—for instance, the vent must be at least 12 inches from any window that can be opened.

- Venting Material: The material used must be rated for the high temperature and corrosive nature of tankless exhaust. For non-condensing units, this is Category III Stainless Steel. For condensing units (the most efficient, which is what we typically install), it is often specialized PVC or Polypropylene (PP) piping. The inspector will confirm the piping and all joints are correctly sealed and supported.

- Condensate Drain: Condensing tankless units produce a mildly acidic liquid condensate. This condensate must be collected and safely drained, usually into an approved drain or neutralizer. The inspector will ensure this is properly tied in to prevent damage to your foundation or plumbing system.

Pillar 3: Prohibited Location and Elevation

The USBC is very strict about where a fuel-fired appliance can be installed to prevent the ignition of flammable vapors or the infiltration of carbon monoxide into living spaces.

- Prohibited Locations: A gas tankless water heater cannot be installed in a closet used for storage, a bedroom, a bathroom, or any location where combustion air is drawn directly from a sleeping area.

- Garage Elevation: If you are installing the unit in a garage (a common location in many Fairfax and Loudoun homes), the pilot light or main burner must be placed at least 18 inches above the floor. This is a safety measure to prevent the ignition of gasoline or other flammable vapors that naturally collect near the floor. We ensure the unit is mounted on the wall or on a platform with the appropriate clearance.

3.3 The Role of the Homeowner and Contractor

This process requires a team effort.

- Your Duty: To hire a licensed, competent contractor and insist on the permit process. You are the ultimate guardian of your home’s safety and value.

- Our Duty: As your contractor, Veteran Plumbing Services takes full responsibility for:

- Securing the appropriate county permits.

- Performing all work to the current Virginia USBC and local amendments.

- Scheduling the inspection and being present to answer any questions the inspector may have.

- Ensuring all safety features, including service valves and the TPR valve, are installed correctly.

By following this disciplined process, we guarantee the safety, legality, and longevity of your new tankless water heating system. Now that the permitting and code requirements are clear, we’ll move on to the actual physical demands of the installation itself. In Chapter 4, we’ll cover where to place the unit, the hard-water issue in Northern Virginia, and the critical need for annual maintenance.

Chapter 4: Installation Requirements, Location, and Hard Water

With the finance mission complete (Chapter 1), the performance requirements defined (Chapter 2), and the critical code compliance framework in place (Chapter 3), we are now ready to discuss the physical execution of the installation.The small, wall-mounted size of a tankless unit is one of its biggest draws—it allows you to reclaim valuable square footage, perhaps turning a utility closet into a pantry or gaining space in your garage. But while tankless units are compact, their placement is governed by strict rules concerning combustion, ventilation, water quality, and accessibility.

This chapter focuses on the practical and environmental concerns unique to the Northern Virginia region: where we can and cannot install the unit, why our local hard water poses a threat, and the non-negotiable requirement for annual maintenance.

4.1 Location, Location, Location: Indoor vs. Outdoor Placement

The most common locations for a tankless unit are in a mechanical closet, utility room, or garage. Their small size makes them incredibly flexible, but the high heat of combustion requires strategic placement and adherence to code.

1. Indoor Installation (The Recommended Choice)

In our service area—from Culpeper’s colder winters to the more temperate coast of Fairfax—we almost always recommend indoor installation for a whole-house unit.

- Venting Demands: The main challenge is installing the complex, code-compliant venting (as discussed in Chapter 3), which must terminate safely outside the structure, usually through a sidewall. This requires precise drilling and sealing.

- Protection from the Cold: Indoor placement protects the unit and its pipes from the prolonged deep freezes we can experience in the winter months. This is critical: if the unit’s freeze protection fails (often due to a prolonged power outage during a deep cold snap), the heat exchanger can freeze and rupture, leading to a catastrophic water leak and replacement cost. Placing the unit indoors mitigates this risk.

2. Outdoor Installation (A High-Risk Option)

Some manufacturers offer weatherized units designed for installation on an exterior wall. While this eliminates the need for expensive indoor venting, I advise most Northern Virginia homeowners against it.

- The Risk of Failure: Although outdoor units come with integrated electric heating elements to prevent freezing, these elements are useless during a power outage. If you lose power for more than a few hours during a sub-freezing night, the unit is at risk of freezing solid.

- Access and Maintenance: The unit is also more exposed to dirt, debris, and corrosion. Maintenance and service become more complicated when the unit is exposed to the elements.

My Professional Verdict: For reliable, year-round operation in our climate, indoor installation is the safer, more disciplined choice.

Code-Mandated Clearances

Beyond the indoor/outdoor decision, we must always adhere to minimum clearances:

- Serviceability: We must ensure there is adequate space around the unit for a technician to access the valves, control panel, and heat exchanger for maintenance and repairs.

- Combustible Materials: The unit must be installed with the manufacturer’s required clearance from any combustible walls or surfaces (often 0–6 inches; verify).

- Prohibited Zones: Again, we never install a unit in a location where the combustion air could be drawn from a sleeping area.

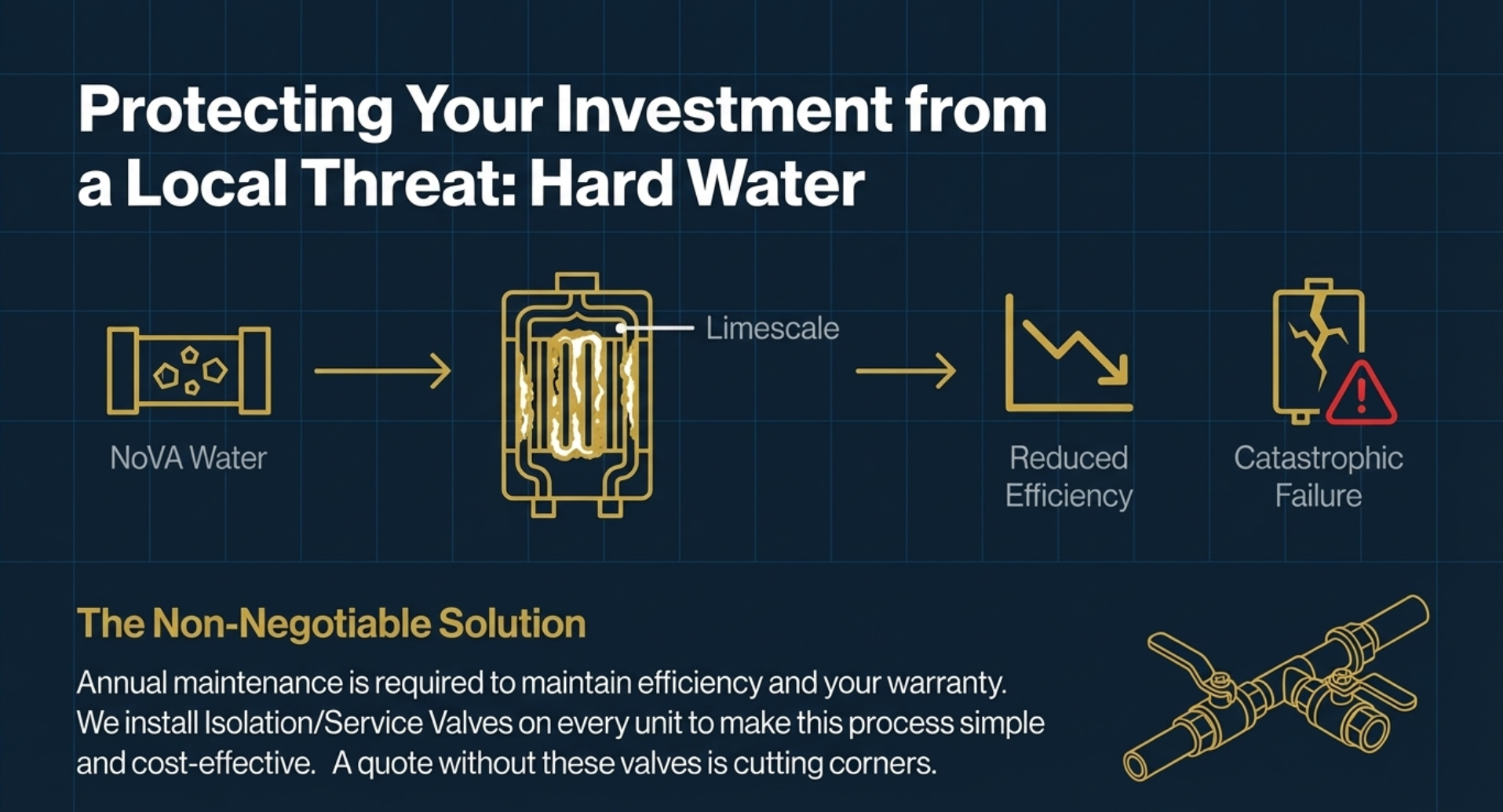

4.2 The Hard Water Challenge in Northern Virginia

The water quality in our service area—particularly the well water in Fauquier and the municipal water supplies in parts of Fairfax and Loudoun presents a specific, ongoing threat to the efficiency and lifespan of a tankless water heater: Hard Water and Limescale.

- The Problem: Hard water contains a high concentration of dissolved minerals, primarily calcium and magnesium. A tankless water heater heats water quickly to a high temperature as it flows through a narrow network of heat-exchanger coils. This high-speed, high-temperature environment is the perfect breeding ground for these minerals to precipitate out of the water and solidify—forming limescale (or “scaling”).

- The Consequences of Scaling:

- Reduced Performance: Limescale acts as an insulator inside the coils, reducing heat transfer efficiency. The unit must work harder and burn more gas to achieve the desired temperature, erasing your energy savings.

- Catastrophic Failure: Severe scale buildup will eventually block the flow of water, causing the unit to cycle on and off (called “short-cycling”) or overheat, leading to expensive repairs or a total system failure.

My Advice to Every Homeowner: You must factor your water quality into your maintenance plan. For most homes in our service area, a properly installed tankless unit is inseparable from a disciplined maintenance schedule.

4.3 The Non-Negotiable Necessity of Annual Maintenance

Because of the hard water conditions we face, annual maintenance is not a suggestion; it is a requirement to maintain the unit’s efficiency, protect your investment, and keep the manufacturer’s warranty valid.

- The Maintenance Process (Flushing and De-scaling): The annual service involves connecting a pump to the unit via specialized valves. We then circulate a non-toxic, mildly acidic solution (like vinegar or a commercial descaler) through the heat exchanger coils for about 45 minutes to an hour. This process dissolves and flushes out all the accumulated limescale, restoring the unit’s efficiency to nearly 100%.

The Critical Component: Isolation/Service Valves

This is a key installation detail where Veteran Plumbing Services excels. We always install a complete set of isolation/service valves (also called flushing ports) on both the hot and cold water lines.

- Why They Matter: Without these valves, flushing the unit is a major, complicated plumbing task. With them, the process is simple, clean, and quick.

- Code and Best Practice: Many local codes and manufacturers now mandate the installation of these valves. Any quote you receive for a tankless installation that does not explicitly include these valves is cutting corners at the expense of your future service cost and the life of your unit.

By choosing a professional who understands the hard water issue and installs the required flushing ports, you are setting your unit up for a long, efficient service life.

With the installation requirements understood, we will now look at the final stages of the process. In Chapter 5, we will detail the step-by-step process of the installation day itself and discuss the complex steps involved in safely connecting the gas and water systems.

Chapter 5: The Installation Day: A Step-by-Step Mission Briefing

From the Desk of Dennis Rollins, U.S. Navy Veteran & Owner, Veteran Plumbing Services

In the Navy, an operation is never successful without meticulous planning and flawless execution. By this point in our guide, you have secured the funding, selected the right high-performance unit, and secured your county permit. Now, it’s time for the physical installation.

This chapter serves as your mission brief for the installation day. It outlines the step-by-step process we follow at Veteran Plumbing Services to ensure a professional, code-compliant, and efficient transition from your old tank to your new, high-efficiency system. Our goal is to minimize disruption to your home in Stafford, Fauquier, or Culpeper and guarantee that the job passes inspection the first time.

5.1 Pre-Installation and Safety Protocol

Before we even touch a wrench, we establish a disciplined workspace.

- Safety and Utility Shutdown: The first step is to shut down the utilities safely:

- Gas: We locate and turn off the main gas service to the old water heater.

- Water: We turn off the cold water supply line.

- Electric: We turn off the power (if the old unit was electric or power-vented).

- Workspace Establishment: We lay down protective drop cloths or runners to shield your floors, especially important if the installation is in a basement or utility room. We ensure a clean, safe path for the transit of tools and materials.

- Old Unit Removal: The old tank is disconnected, completely drained (often a few messy gallons remain), and carefully removed from the home for proper, environmentally responsible disposal. We remove not just the tank, but the old, non-code-compliant venting and the undersized gas line segment.

5.2 The Core Infrastructure Upgrade: Gas, Water, and Venting

This is the most critical and time-consuming phase, defining the complexity of a tankless installation versus a simple tank replacement. This work is why you hire a certified Master Gasfitter.

Step 1: Gas Line Upgrade (The Fuel Supply)

As discussed in Chapter 1, this step is often non-negotiable for safety and performance:

- Piping Run: We run the new, larger diameter gas pipe (often 3/4″ or 1″) from the main supply or manifold to the new unit’s exact location. This run is performed according to the specific sizing calculations we submitted to the county for the permit.

- Leak Testing: Before connecting the unit, we perform a pressure test on the new gas line segment to ensure all joints and connections are perfectly sealed. Safety first means zero tolerance for gas leaks.

Step 2: New Venting System Installation (The Exhaust)

This task requires specialized material handling and precise drilling.

- Wall Penetration: If the unit is power-vented through the sidewall, we drill the required penetration point. This hole must be perfectly sized, sealed against water intrusion, and correctly located to meet the clearance requirements from windows and doors (as checked in the inspection).

- Venting Pipe Assembly: We assemble the specialized Category III Stainless Steel or PVC venting pipe, ensuring all joints are correctly glued and fully sealed to prevent any exhaust gases from escaping into your home. The vent line is run with the proper slope back to the unit for safe operation.

Step 3: Plumbing and Isolation Valve Installation

The plumbing connections are critical for both flow and future maintenance.

- Water Line Installation: We install the new hot and cold water lines, ensuring they are sized (often 3/4″) to handle the high flow rate of the tankless unit.

- Installation of Isolation/Service Valves (Mandatory): We install the dedicated set of isolation valves on the hot and cold lines. This is a crucial safety and maintenance feature, allowing us to isolate the unit for de-scaling without shutting off the main water supply to your home. We install the drain for the pressure relief valve.

- Condensate Drain: If you have a high-efficiency condensing unit (which we recommend), we install the specialized, acid-resistant drain line to safely collect and neutralize the condensate before it enters your home’s plumbing system.

5.3 Final Connections, Commissioning, and Testing

With the infrastructure complete, we move to the final hookups, ensuring every connection is secure and the unit is operating to peak efficiency.

Step 4: Mounting and Final Connections

- Unit Mounting: The unit is securely mounted to the wall, often with a structural mounting plate to handle its weight.

- Gas Connection: The gas line is connected to the unit, and a final localized gas-leak test is performed using a specialized gas detector and a soap solution.

- Water Connection: The water lines and the Temperature and Pressure Relief (TPR) valve are connected. The TPR valve is a non-negotiable safety feature designed to release pressure if the unit overheats.

- Electrical: The small electrical connection for the fan and control board is wired in (this is a small draw, unlike the massive draw of an electric tankless unit).

Step 5: Commissioning and Performance Testing

- System Activation: We turn on the gas and water supplies and bleed the air from the lines.

- Performance Check: We fire up the unit and perform a series of functional tests:

- Temperature Output Test: We measure the water temperature at various fixtures to confirm it reaches a stable, consistent 120°F.

- Flow Rate Test (The “Mission Success”): We run multiple fixtures simultaneously (e.g., a shower and a sink) to verify that the GPM output remains stable and the unit does not short-cycle.

- Venting Inspection: We perform a final check of all venting seals and ensure that no carbon monoxide is present near the unit or at the vent termination point.

5.4 Preparing for Inspection

Upon completion of the work, the site is cleaned, and all debris and the old water heater are removed. The unit is fully operational, providing your family with immediate, endless hot water.

The Final Step: We contact the county to schedule the Final Inspection—usually a simple call, since the rough-in work has been pre-approved by the permit. We ensure a representative from Veteran Plumbing Services is present during the inspection to answer any questions the county official may have regarding our adherence to the USBC and local codes.

With the installation mission complete, we move on to the final chapter. In Chapter 6, we will equip you with the knowledge to vet any plumber you hire and understand the final safety checks the county will perform, ensuring your investment is secure for years to come.

Chapter 6: Vetting Contractors and Final Inspection

We have now reached the final and arguably the most crucial step in the tankless water heater process: hiring the right partner and securing final approval from the county.

As a Navy Veteran, I know that success is determined by the quality of the team you assemble. Installing a high-BTU gas appliance in your home is not a job for a handyman or a general plumber who “also does water heaters.” It requires a specialist—a licensed Master Gasfitter who understands the complexities of the Virginia Uniform Statewide Building Code (USBC) and the specific amendments in your county, whether it’s Loudoun, Fairfax, or Stafford.

This chapter provides you with the final tools to vet any contractor you consider, understand what a professional quote should contain, and know exactly what the county inspector will be looking for to give your installation the final stamp of safety and approval.

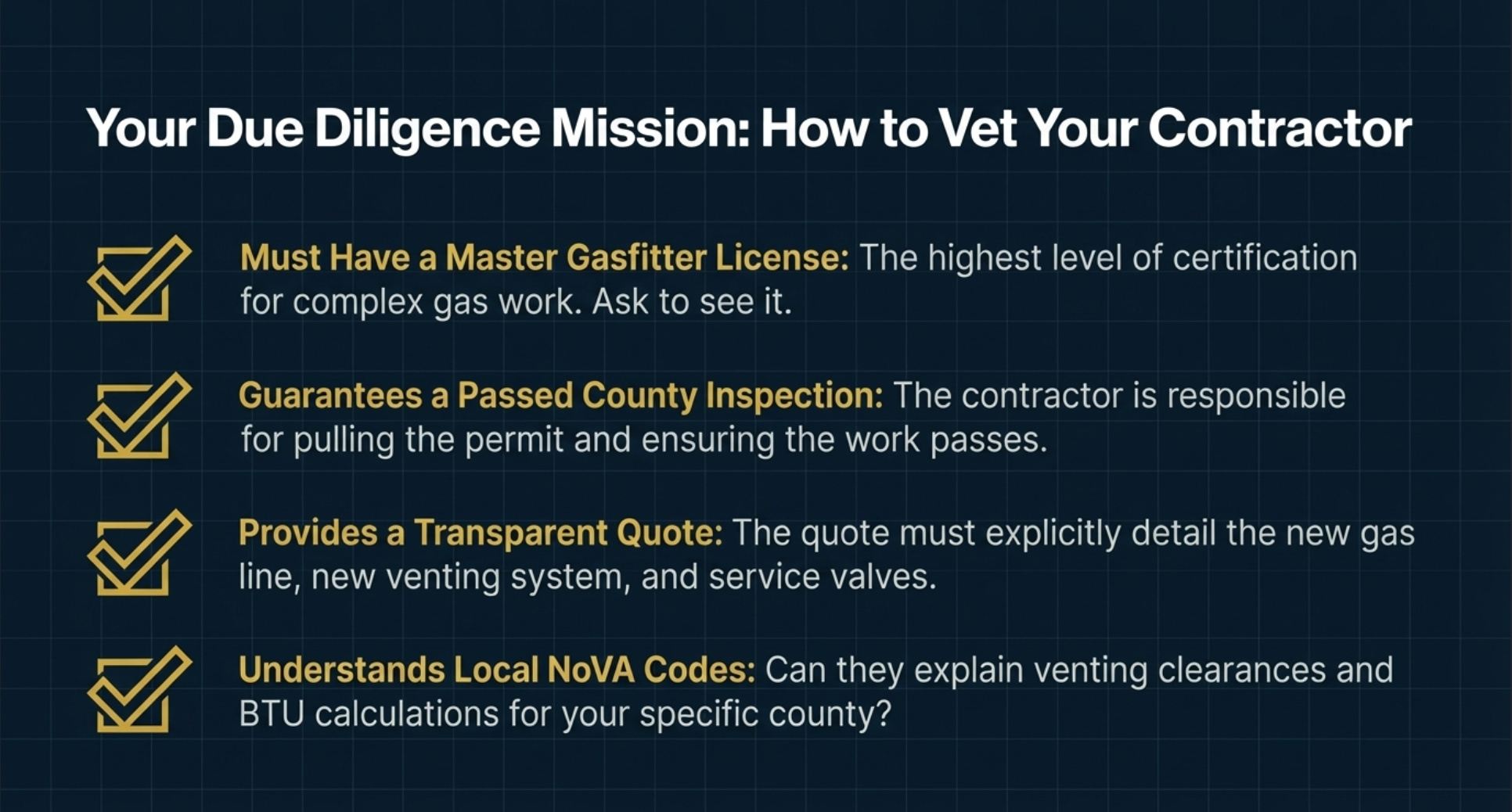

6.1 Vetting Your Contractor: The Due Diligence Mission

Do not take a risk on the safety of your home to save a few hundred dollars. Use this checklist to screen any potential contractor:

1. Demand to See State and Trade Licenses (The Non-Negotiable)

- Virginia State Contractor’s License: They must have an active license (Class A, B, or C, depending on the project size). A legitimate company will proudly display this number.

- Master Gasfitter/Master Plumber License: This is the most critical license. A plumber may be a Journeyman, but only a Master Gasfitter has the highest level of certification and experience required to safely alter and install the complex, high-pressure gas lines and high-temperature venting systems of a tankless unit. If the contractor cannot immediately produce proof of a Master Gasfitter license, stop the conversation.

2. Test Their Knowledge of Local Code (The Competence Check)

Ask targeted questions that only a locally experienced professional can answer:

- Gas Line Sizing: “What are the required BTU calculations you use to size the gas line for a 199,000 BTU unit in my area?” (They should reference the NFPA 54 code and mention the required pipe diameter for the length of your run.)

- Venting Clearances: “If I place the unit in the garage, what is the distance your vent termination must be from the nearest window, according to Fairfax County/Prince William County code?” (They should know the specific horizontal and vertical clearances defined by the USBC.)

- Permit Guarantee: “Will you guarantee that the installation will pass the final county inspection?” (They should offer this guarantee, as they are responsible for pulling and passing the permit.)

3. Analyze the Quote (The Transparency Check)

A professional quote from Veteran Plumbing Services will never be the lowest, but it will be the most transparent and comprehensive. Ensure your quote explicitly includes:

| Item | What a Professional Quote Includes | What an Amateur Quote Leaves Out |

| Permit | Explicit cost for County Permit and Inspection fees. | “We don’t need a permit,” or “The homeowner handles the permit.” |

| Gas Line | New, upgraded gas line material and labor (e.g., “25 feet of 3/4” gas pipe upgrade”). | “We will connect to existing gas line.” (A guarantee of a failed inspection). |

| Venting | Venting system material (e.g., “Category III Stainless Steel or PVC system”) and labor for installation. | Vague “Vent Kit” or no mention of the required material. |

| Maintenance | Isolation/Service Valves installation included as a standard safety/maintenance feature. | Zero mention, forcing you to pay for a complex valve installation later. |

6.2 The Final Inspection: Securing Your Investment

Once the installation is complete and our technician has thoroughly tested the unit, the final step is the county’s inspection. This is the government’s way of verifying that all safety precautions and code requirements have been met.

Remember: If the contractor pulls the permit, the contractor is responsible for ensuring the work passes inspection. My team is committed to the highest standards, and we always aim for a first-pass inspection.

The Inspector’s Final Checklist (What They Will Be Looking For)

The inspector will spend time reviewing the safety and serviceability features of the installation:

- Safety and Clearance Verification (The Red Flag Check):

- Venting Clearances: Is the vent termination the required distance from any openable windows, doors, or air intakes?

- Prohibited Location: Is the unit located legally (e.g., not in a bedroom or a prohibited closet)?

- Garage Elevation: If applicable, is the ignition source at least 18 inches above the garage floor?

- Infrastructure Verification (The Performance Check):

- Gas Line Sizing: Does the new gas line visually match the required size, and is there evidence of a successful pressure test?

- New Venting Material: Is the venting material (e.g., stainless steel or PVC) correct for the type of tankless unit installed?

- Serviceability Verification (The Longevity Check):

- TPR Valve: Is the Temperature and Pressure Relief valve installed correctly, and does its discharge line terminate safely (usually within 6 inches of the floor)?

- Isolation/Service Valves: Are the mandatory service valves installed to enable easy, annual descaling and maintenance?

When your installation passes inspection, you receive the final county sign-off. This document is crucial because it legally verifies your new appliance is safe and code-compliant—a detail your insurance company and any future buyer of your home (especially in the competitive NoVA real estate market) will require and value.

Conclusion: Your Mission is Complete

Congratulations. By reading this guide, you have moved from a curious homeowner to a fully informed, disciplined consumer. You now understand the financial rationale, the technical demands, the critical code compliance unique to Fairfax, Loudoun, Prince William, and surrounding counties, and the necessary maintenance required to sustain your investment.

At Veteran Plumbing Services, we bring a veteran’s dedication and discipline to every tankless water heater we install. We don’t cut corners. We pull the permits, we size the gas lines correctly, and we guarantee the quality of our work for the safety and long-term satisfaction of your family.

If you are ready to install a tankless water heater with the peace of mind that comes from a perfectly executed, code-compliant job, call us. We stand ready to serve your home in Northern Virginia.

Dennis Rollins, U.S. Navy Veteran

Owner, Veteran Plumbing Services

I’m Dennis Rollins. I served my country, and now I’m here to help you protect your home.

Source List

1. Energy Efficiency Statistics

ENERGY STAR. (n.d.). Tankless Water Heater: Saves Energy & Money. Retrieved from https://www.energystar.gov/products/water_heaters/tankless_gas_water_heater

2. Federal Tax Credit Information

Energy Star. (n.d.). Energy Efficient Home Improvement Credit. Retrieved from https://www.energystar.gov/about/federal_tax_credits/energy_efficient_home_improvement_credit

3. Local Utility Rebate (Washington Gas)

Washington Gas. (n.d.). Natural Gas Tankless Water Heater Rebate (Virginia). Retrieved from https://www.washingtongas.com/save-energy-money/rebates/virginia-natural-gas-tankless-water-heater-rebate

4. Local Utility Rebate (Columbia Gas of Virginia)

Columbia Gas of Virginia. (n.d.). WarmWise Rebates for Residential Customers. Retrieved from https://www.columbiagasva.com/ways-to-save/warmwise-rebates/residential-customers

5. Virginia Statewide Building Code (Source of Code Compliance)

Virginia Department of Housing and Community Development. (n.d.). Virginia Uniform Statewide Building Code (USBC). Retrieved from https://www.dhcd.virginia.gov/building-codes

6. Example Local Permit Authority (Fairfax County)

Fairfax County, Virginia. (n.d.). Plumbing & Gas Permits. Retrieved from https://www.fairfaxcounty.gov/landdevelopment/plumbing-gas-permits